Same-day dental implants for a simplified experience.

The Orwell system enables a patient’s dental implant treatment to be finalised within a single day through the integration of hard tissue engineering and Solid Free Form fabrication (SFF). Information of a patient’s bite is captured using a 3D intra-oral scanner, which in turn develops a unique implant using the integrated CAD facility. Fabrication of a biologically-active implant is then carried out via an innovative selective laser sintering unit.

The Orwell system enables a patient’s dental implant treatment to be finalised within a single day through the integration of hard tissue engineering and Solid Free Form fabrication (SFF). Information of a patient’s bite is captured using a 3D intra-oral scanner, which in turn develops a unique implant using the integrated CAD facility. Fabrication of a biologically-active implant is then carried out via an innovative selective laser sintering unit.

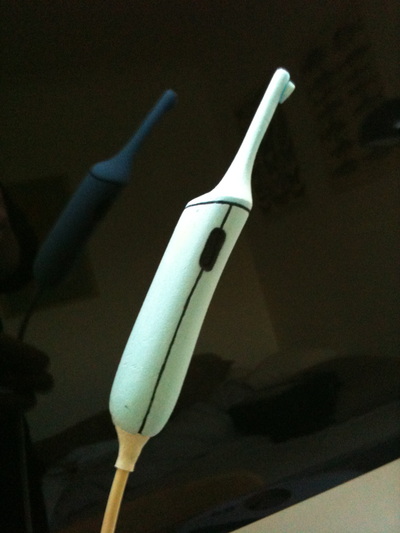

Intra-Oral Scanning.

Finite Element Analysis (FEA) is used within the CAD software to accurately predict the mechanical strength and overall properties of the implant prior to sintering. A biochemical analysis of the tooth allows accurate predictions for bone integration of the tooth into the existing jawbone, as well as calculating periods before patients should eat certain types of foods which may affect the implant in its early stages.

Finite Element Analysis (FEA) is used within the CAD software to accurately predict the mechanical strength and overall properties of the implant prior to sintering. A biochemical analysis of the tooth allows accurate predictions for bone integration of the tooth into the existing jawbone, as well as calculating periods before patients should eat certain types of foods which may affect the implant in its early stages.

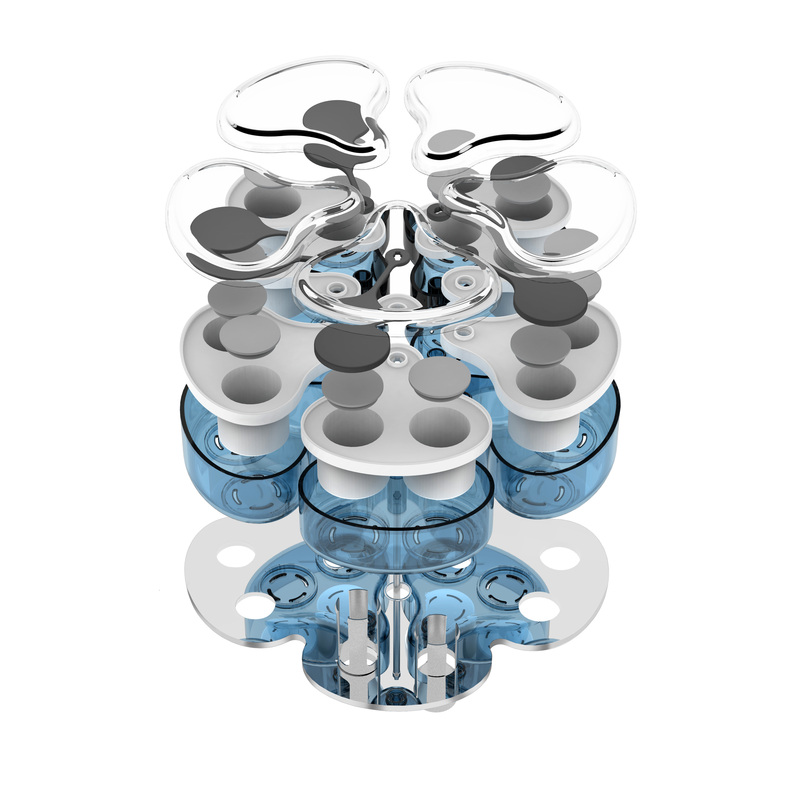

Orwell Selective Laser Sintering System.

The Orwell sintering system is based on the premise of traditional laser sintering techniques whereby a laser beam is directed about an X and Y axis through the use of reflective optics. Layer by layer, cross sections or slices of the CAD-generated implant are fabricated on top of one another.

The Orwell sintering system is based on the premise of traditional laser sintering techniques whereby a laser beam is directed about an X and Y axis through the use of reflective optics. Layer by layer, cross sections or slices of the CAD-generated implant are fabricated on top of one another.

|

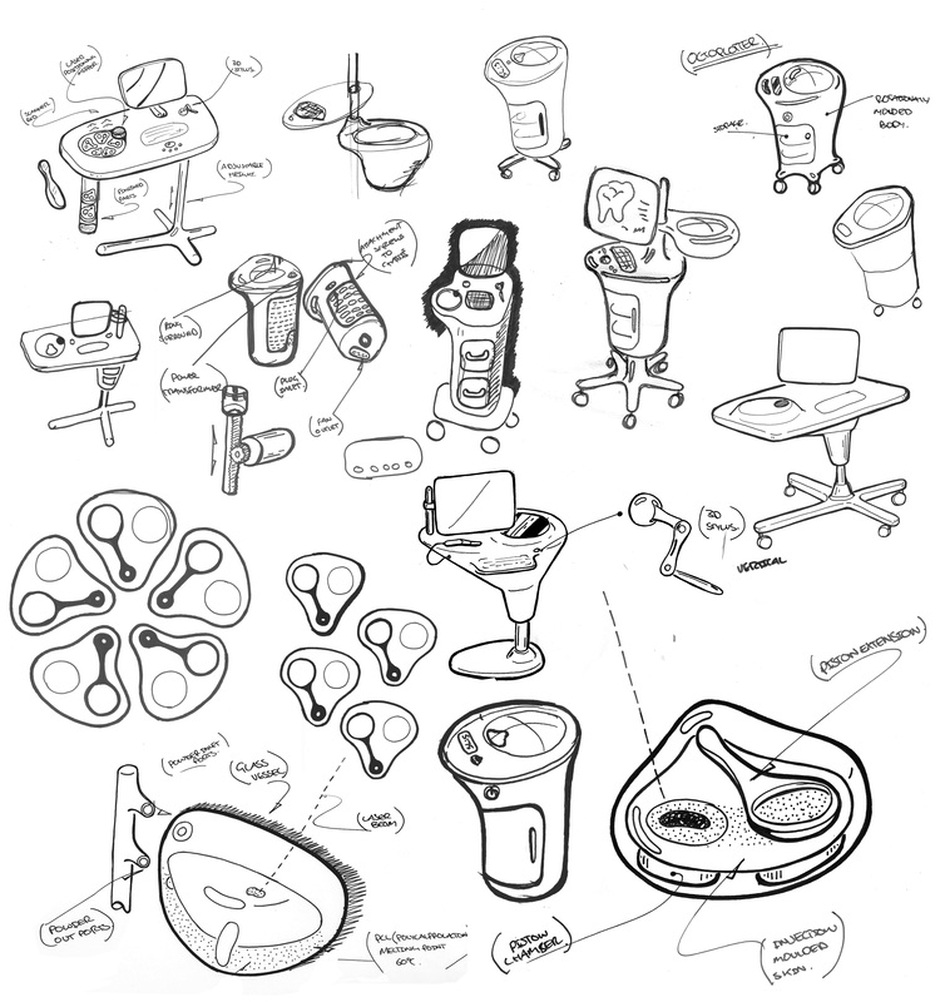

Concept Development.

The Orwell design evolved through a number of sketch and 3D iterations with academic reviews, market research, mock-ups and scenario testing. Surface modelling combined with parametric modelling facilitated periodic aesthetic and functional evaluation through on- screen presentations and 3D printed prototype components. Prototype Development.

A variety of foam core and blue foam mock-ups were created as well as a final prototype which incorporated a number of proprietary components with unique CAD-driven prototype parts. The final 1:1 scale model was created through MDF modelling, blue foam sculpting, SLS 3D printing, laser cutting, CNC machining and sheet metal fabrication, as well as final filling, joining, and spray paint finishing. |